Modern Manufacturing & Robotics Systems on Supply Chain Investment Trends, Costs, and Technological Advancements

The rise of Industry 4.0 technologies, such as AI, robotics, and IoT, is reshaping how manufacturing and supply chains operate. According to data provided by Precedence Research, companies like Hyundai and Walmart are making substantial investments in automation, digital twins, and AI-powered robotics. This digital transformation is improving operational efficiency, reducing downtime, and creating more resilient, adaptable supply chains. These advancements, coupled with growing adoption rates of smart manufacturing tools, are expected to drive a significant increase in industry-wide investments.

Ottawa, Feb. 06, 2026 (GLOBE NEWSWIRE) -- According to Precedence Research, the industrial robotics and smart manufacturing sectors are undergoing a significant transformation, fueled by investment in automation, AI, and advanced robotics. Over the next decade, the demand for industrial robots is expected to grow steadily, with costs for both manufacturing and purchasing robotics systems gradually increasing. Companies across the globe are prioritizing smart factory initiatives, IoT integration, and supply chain digitization to improve efficiency and adaptability. This article explores current trends, investment figures, and technological impacts shaping modern manufacturing and its associated supply chains.

Invest in Our Premium Strategic Solution: https://www.precedenceresearch.com/request-consultation/47

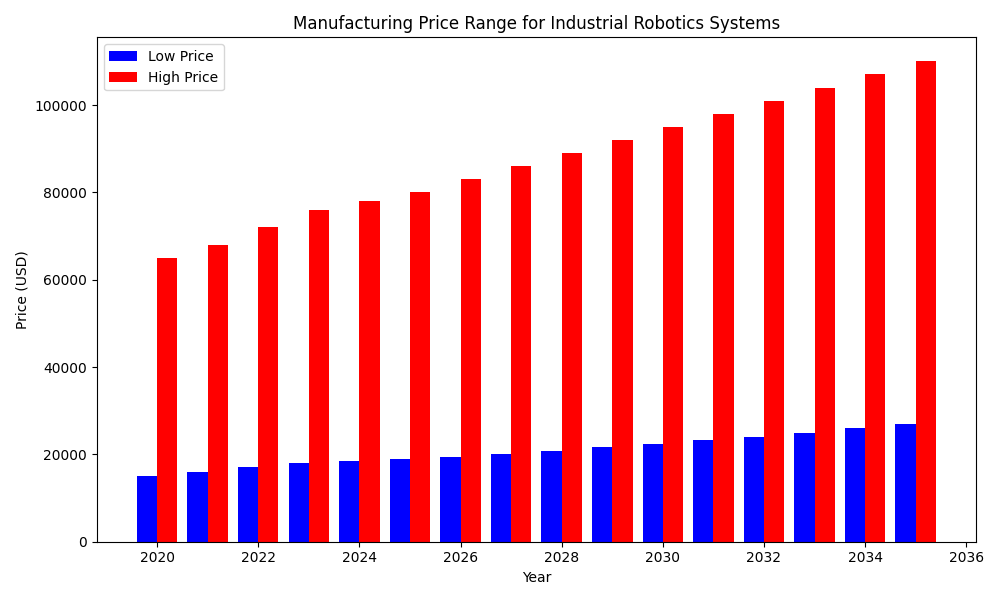

Manufacturing Price Ranges for Robotics Systems

As industries embrace automation, the cost of industrial robots has become a critical consideration for manufacturers. The prices of robots vary depending on payload, capabilities, and other specifications. The following table highlights the typical manufacturing cost ranges for industrial robots over recent years.

Manufacturing Price Range for Industrial Robotics Systems

| Year | Low (USD) | High (USD) |

| 2020 | 15,000 | 65,000 |

| 2021 | 16,000 | 68,000 |

| 2022 | 17,000 | 72,000 |

| 2023 | 18,000 | 76,000 |

| 2024 | 18,500 | 78,000 |

| 2025 | 19,000 | 80,000 |

| 2026 | 19,500 | 83,000 |

| 2027 | 20,000 | 86,000 |

| 2028 | 20,800 | 89,000 |

| 2029 | 21,600 | 92,000 |

| 2030 | 22,400 | 95,000 |

| 2031 | 23,200 | 98,000 |

| 2032 | 24,000 | 101,000 |

| 2033 | 25,000 | 104,000 |

| 2034 | 26,000 | 107,000 |

| 2035 | 27,000 | 110,000 |

Key Insights:

- The low-end of the price range (~15,000) represents entry-level robots designed for simple tasks.

- The high-end (~107,000) is typically for larger robots with more complex capabilities such as higher payloads, multi-axis motion, and precision applications.

- The forecast reflects gradual improvements in robot manufacturing, driven by advances in sensors, motors, and controllers.

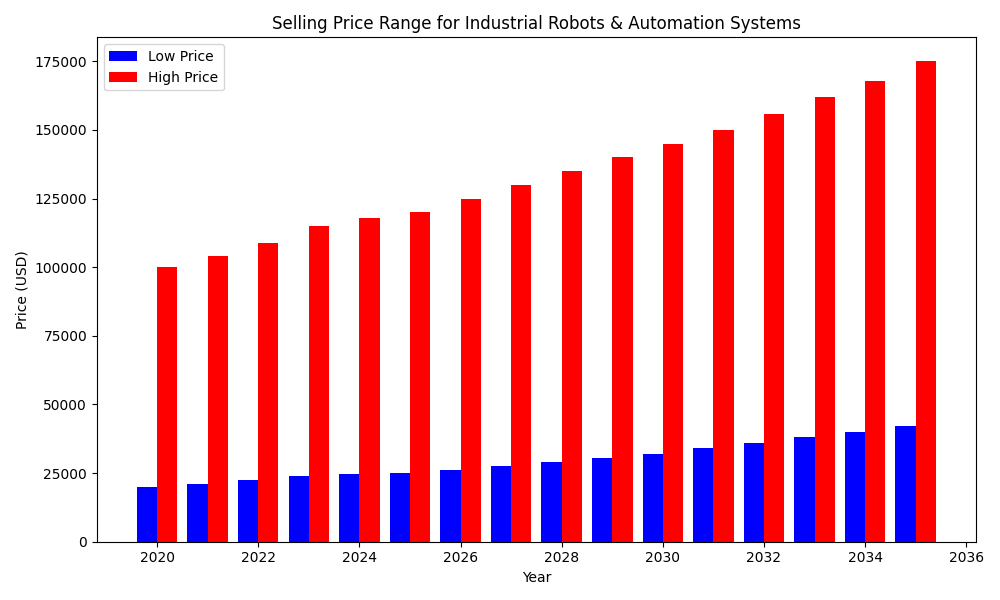

Selling Price Range for Industrial Robots & Automation Systems

As manufacturers implement automation solutions, the selling prices of industrial robots also include markups for additional services such as software integration, installation, and warranties.

| Year | Low (USD) | High (USD) |

| 2020 | 20,000 | 100,000 |

| 2021 | 21,000 | 104,000 |

| 2022 | 22,500 | 109,000 |

| 2023 | 24,000 | 115,000 |

| 2024 | 24,500 | 118,000 |

| 2025 | 25,000 | 120,000 |

| 2026 | 26,000 | 125,000 |

| 2027 | 27,500 | 130,000 |

| 2028 | 29,000 | 135,000 |

| 2029 | 30,500 | 140,000 |

| 2030 | 32,000 | 145,000 |

| 2031 | 34,000 | 150,000 |

| 2032 | 36,000 | 156,000 |

| 2033 | 38,000 | 162,000 |

| 2034 | 40,000 | 168,000 |

| 2035 | 42,000 | 175,000 |

Key Insights:

- The low-end price range starts from ~20,000, covering basic automation systems and robots.

- The high-end price reflects complete automation systems with advanced functionalities such as full integration with existing infrastructure, specialized software, and enhanced maintenance support.

Modern Manufacturing & Supply Chain Transformation

The rise of Industry 4.0 technologies has led to a massive shift in manufacturing practices. This shift is powered by technologies such as IoT, AI, machine learning, and robotics, which are improving real-time visibility, reducing downtime, and increasing overall production efficiency.

Industry 4.0 Technologies Driving Digital Manufacturing

- IoT: Connecting devices and machines to collect real-time data across production lines, allowing for better decision-making.

- AI & Machine Learning: Used for predictive maintenance, supply chain forecasting, and process optimization.

- Robotics: Automation in production, material handling, and logistics is increasing efficiency and reducing human error.

- Cloud Platforms: Facilitate real-time data sharing and management across the supply chain.

Key Benefits:

- Real-time Product Tracking: Enhances supply chain visibility, making it easier to trace products and manage inventory.

- Predictive Analytics: Allows manufacturers to forecast demand and reduce waste, while predictive maintenance minimizes downtime.

-

Automation: Reduces manual labor, improves production speeds, and increases precision in manufacturing processes.

Real-World Strategic Company Initiatives

Several companies are making significant strides in digital manufacturing and supply chain optimization. Below are examples of major initiatives:

| Company / Initiative | Investment / Data | Technology Impact | Supply Chain Benefits |

| Hyundai Motor Group | 7.6B investment in AI-powered smart plant | Full automation, digital twins, and robotics | Improved quality control, reduced downtime, enhanced adaptability to supply disruptions |

| Walmart (Retail Supply Chain) | Deploying IoT sensors across 90 million pallets | Real-time tracking and condition data | Improved inventory management and demand forecasting |

| Enmovil (AI Supply Chain Platform) | Raised ~6M Series A funding | AI-driven demand forecasting, ERP integration | Improved planning and supply chain visibility |

| KION Group | €11.5B revenue, investing in AI + digital twins | Real-time simulation of operations | Enhanced warehouse automation and logistics flexibility |

| Swisslog Holding AG | €772M revenue (2024) | Automated material handling | Reduced cycle times and increased throughput |

| General Electric Company (GE) | Investments in Industry 4.0 automation | IoT, automation, data analytics | Improved manufacturing process efficiency |

| Siemens | Leading smart manufacturing solutions | IoT, automation platforms | Enhanced production visibility and supply chain integration |

| ABB | Advanced manufacturing and automation | Robotics, AI, process automation | Increased precision, faster production, and improved supply chain throughput |

| Tesla, Inc. | Advanced automated gigafactories | Automated guided vehicles, robotics | Scalable production lines with high automation |

Key Insights:

- Companies like Hyundai and Walmart are heavily investing in AI-powered automation, IoT sensors, and robotics to drive operational efficiency and improve supply chain management.

- Initiatives in automation, predictive maintenance, and AI integration are allowing companies to enhance their supply chain resilience and agility.

The Future of Manufacturing & Supply Chain Automation

The rapid evolution of smart manufacturing technologies, driven by Industry 4.0, is transforming the global supply chain landscape. Investments in robotics, AI, and IoT are enabling companies to optimize production processes, improve supply chain visibility, and create more adaptable operations. As costs for robotics systems gradually increase, companies are leveraging these technologies to enhance operational efficiency and gain a competitive edge. Moving forward, the integration of these technologies will continue to reshape industries, making supply chains more resilient, efficient, and responsive to future challenges.

What is the Healthcare Supply Chain Management Market Size?

The global healthcare supply chain management market size is calculated at USD 3.95 billion in 2025 and is predicted to increase from USD 4.16 billion in 2026 to approximately USD 6.32 billion by 2034, expanding at a CAGR of 5.35% from 2025 to 2034. The growth of the market is driven by rising demand for medical products and transparency in supply chains. Additionally, the rising adoption of AI, IoT, cloud, and blockchain technologies to enhance security in supply chains contributes to market growth.

Request Research Report Built Around Your Goals: sales@precedenceresearch.com

About Us: Precedence Research

Our Legacy: Rooted in Research, Focused on the Future

Looking for research that drives real results? Precedence Research delivers strategic, actionable insights, not just data and charts. Based in Canada and India, our team specializes in customized market analysis, executive-level consulting, and tailored research solutions that go beyond traditional survey methodologies to support business growth with precision and confidence.

Insight-Driven

We turn complex data into clear, strategic insights that power confident business decisions.

Innovation-Led

We continuously refine our methods to stay ahead of trends and emerging market forces.

Industry-Agnostic

From tech to healthcare, we serve clients across sectors with tailored, actionable intelligence.

Customer-Centric, Future-Focused, Result-Oriented

We work as strategic partners, engaging deeply with clients to co-create impactful solutions.

Our Commitment: Delivering Intelligence That Drives Transformational Growth

What do we do? We turn data noise into clarity. Through sharp research, agile thinking, and tech-enabled tools, we fuel brands, disrupt markets, and lead with insight that drives unstoppable growth.

Contact Us

USA: +1 8044 419344

APAC: +61 4859 81310 or +91 87933 22019 or +6531051271

Europe: +44 7383 092 044

Email: sales@precedenceresearch.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.